polySpectra Products

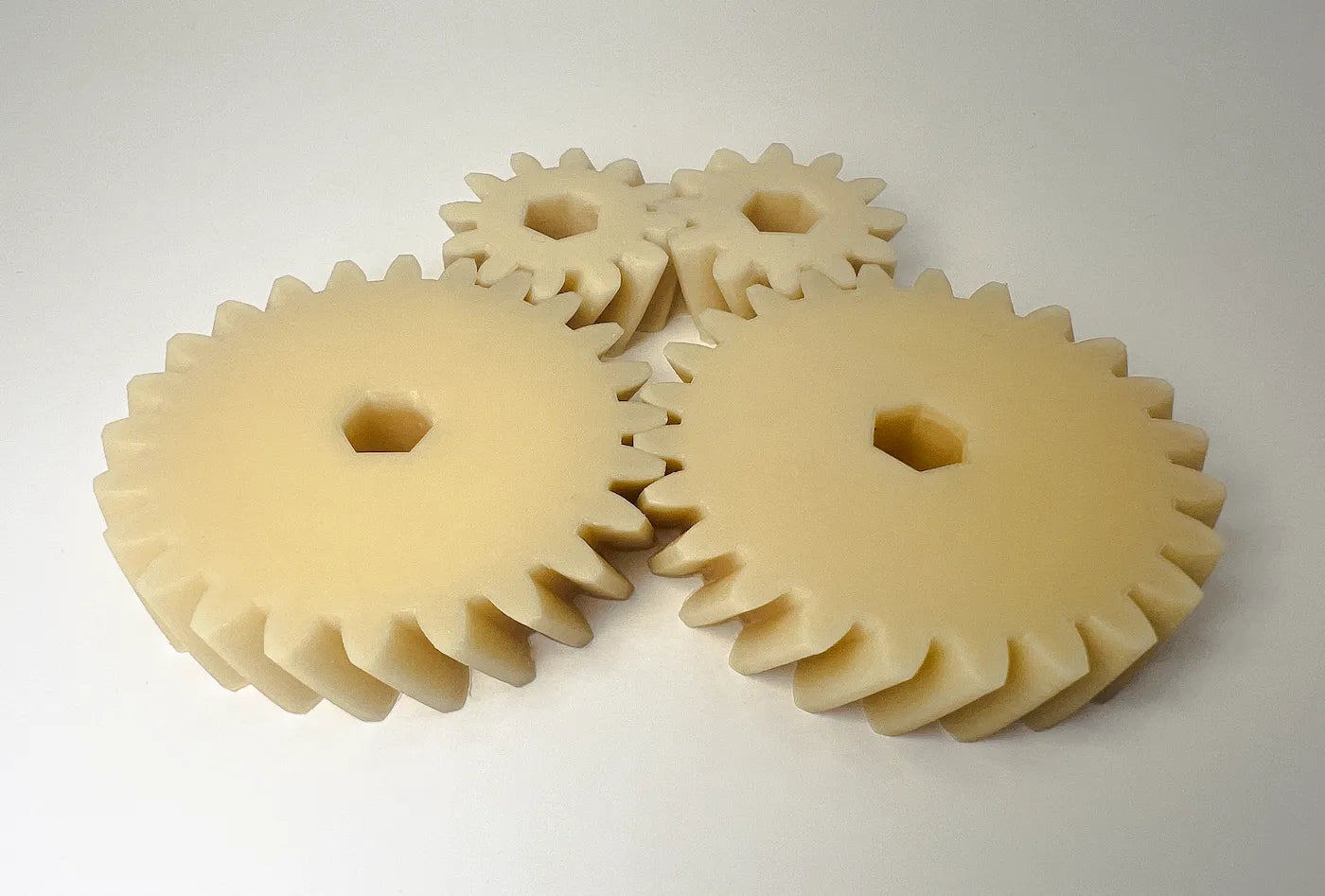

ThOR 10 Composite Photopolymer Resin for 405nm DLP & LCD 3D Printers

ThOR 10 Composite Photopolymer Resin for 405nm DLP & LCD 3D Printers

Couldn't load pickup availability

[Launch Note: 405nm ThOR 10 currently has a 3-4 week lead time]

ThOR 10 is a rugged, 10% glass-filled composite photopolymer resin delivering an exceptional balance of impact strength, thermal stability, and stiffness. What makes ThOR 10 stand out?

- Excellent impact resistance (Notched Izod 55 J/m, Un-notched Izod 360 J/m)

- High working temperature (Glass transition 131 °C)

- Good ductility (> 20% elongation at break)

- Enhanced stiffness (Tensile Modulus 2.0 GPa) due to glass filler

- Extreme chemical resistance inherent to the Cyclic Olefin Resin base

Important Notice: ThOR 10 photopolymer resin is intended for use by trained additive manufacturing professionals working in industrial, manufacturing, and laboratory facilities. At this time, we discourage printing with ThOR 10 in home or office environments. We reserve the right to cancel your resin purchase if you cannot meet the safety requirements. If you do not have access to this type of facility or training, we would be happy to print ThOR 10 parts for you at https://polyspectra.com/start-here !

Please Review All of the Requirements Before Placing Your Order

Questions? Just give us a call 510 390 9145 or email support@polyspectra.com

Facilities Requirements:

- Well-ventilated print and part-cleaning areas

- Chemical waste disposal (for used resin and used part-cleaning solution)

- Read the SDS => https://geni.us/ThOR-10-SDS

Equipment Requirements:

- Printer Ventilation: A well-ventilated 385nm or 405nm DLP/LCD 3D printer

- (see docs.polySpectra.com for validated/exploratory printer lists and ventilation suggestions)

- Refrigerated Storage: A refrigerator or freezer to store resin below 5 °C

- Please note to refrigerate on arrival

- Warm Before Printing: An oven or warm water bath to warm the resin to 40 °C

- (see docs.polySpectra.com for the validated resin warming procedure)

- Ventilated Cleaning Area: A well-ventilated area to clean parts

- (see docs.polySpectra.com for examples and recommendations)

- Post-Curing Oven: A vacuum oven, or exploratory post-cure unit

- (see docs.polySpectra.com for the validated and exploratory equipment lists)

PPE Requirements:

- Read the SDS => https://geni.us/ThOR-10-SDS

- Nitrile gloves

- Safety glasses

- Lab coat

- Long pants

- Close-toed shoes

Consumables Requirements:

- polySpectra SupaRinse is our validated part-cleaning solution

- Please contact our team to try SupaRinse support@polyspectra.com

- A list of exploratory alternative cleaning solutions and solvents can be found at docs.polySpectra.com

Training Requirements:

- Trained additive manufacturing professional

- Experience in the safe operation of SLA/DLP/LCD resin 3D printers

- Training in the cleaning, post-curing, and finishing of printed parts

- Training in the proper handling of resin, cleaning solvents, and chemical waste

By placing an order for ThOR 10 resin, you are attesting that the facility, equipment, and personnel at the shipping address meet the safety and training requirements above. We reserve the right to cancel your resin purchase if you cannot meet the safety requirements. If you do not have access to this type of facility, equipment or training --- we would be happy to print ThOR 10 parts for you at https://polyspectra.com/start-here !